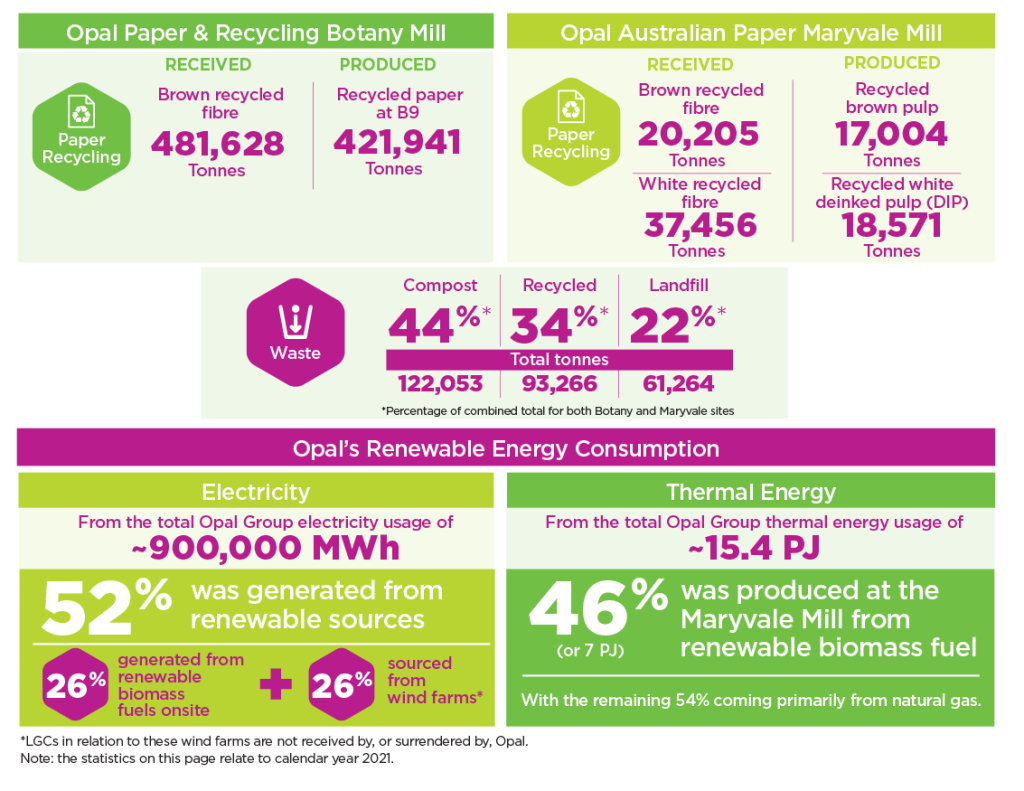

Committed to a circular economy approach

The circular economy creates new possibilities, extending the life of products and resources, to benefit all of society, reduce business costs and our impact on the planet.

Opal is committed to sustainable circular economy business practices that reduce our environmental impact, support our local communities and contribute to a strong economy.